Collection: Meat Processing Equipment

-

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $5,436.67 CADSale price $5,436.67 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $7,446.60 CADSale price $7,446.60 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $2,575.40 CADSale price $2,575.40 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $2,952.13 CADSale price $2,952.13 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $1,739.86 CADSale price $1,739.86 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $2,705.31 CADSale price $2,705.31 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroom1-3 Week Lead TimeRegular price $1,932.36 CADSale price $1,932.36 CAD Regular priceUnit price / per

$0.00 CAD -

Vollrath Medium Duty Meat Slicer, 10", 1/3 HP - 40950

SKU: 1900/40950showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $2,624.06 CADSale price $2,624.06 CAD Regular priceUnit price / per$0.00 CAD -

Vollrath Medium Duty Meat Slicer, 12", 2/5 HP - 40951

SKU: 1900/40951showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $3,585.25 CADSale price $3,585.25 CAD Regular priceUnit price / per$0.00 CAD -

Vollrath Heavy Duty Meat Slicer, 12", 1/2 HP - 40952

SKU: 1900/40952showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroom1-3 Week Lead TimeRegular price $4,917.65 CADSale price $4,917.65 CAD Regular priceUnit price / per$0.00 CAD -

Eurodib HBS Series 8" Slicer w/ Locking System, 120V - HBS195JS

SKU: 582/HBS195JSshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $640.37 CADSale price $640.37 CAD Regular priceUnit price / per$0.00 CAD -

Final Sale

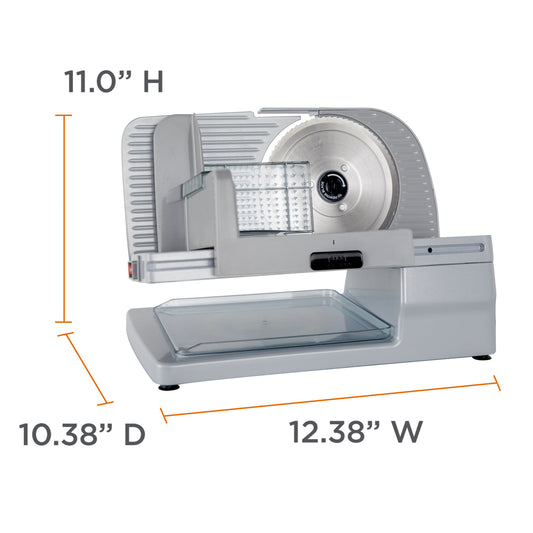

Chef'sChoice Model 615A Electric Food Slicer, Grey, 120V - 615A000

SKU: 006/615A000showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $228.89 CADSale price $228.89 CAD Regular priceUnit price / per$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $3,556.38 CADSale price $3,556.38 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $2,414.78 CADSale price $2,414.78 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $2,409.77 CADSale price $2,409.77 CAD Regular priceUnit price / per

$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $2,945.64 CADSale price $2,945.64 CAD Regular priceUnit price / per

$0.00 CAD -

Globe Meat Grinder Assembly with #12 Hub - XMCA-SS

SKU: 817/XMCA-SSshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $1,653.06 CADSale price $1,653.06 CAD Regular priceUnit price / per$0.00 CAD -

Final Sale

Chef'sChoice Model 720 Food / Meat Grinder, Stainless Steel/Cast Aluminum - 7200000

SKU: 006/7200000showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $333.06 CADSale price $333.06 CAD Regular priceUnit price / per$0.00 CAD -

Final Sale

Globe Manual Patty Press, 5", FINAL SALE - PP5

SKU: 817/PP5showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroom1-3 Week Lead TimeRegular price $561.34 CADSale price $561.34 CAD Regular priceUnit price / per$0.00 CADSold out -

Rabco Manual Hamburger Patty Press, 5", Aluminum - MAG3670

SKU: 376/MAG3670showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomAvailable to shipRegular price $37.39 CADSale price $37.39 CAD Regular priceUnit price / per$0.00 CAD -

showroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroom1-3 Week Lead TimeRegular price $346.00 CADSale price $346.00 CAD Regular priceUnit price / per

$0.00 CAD -

Prince Castle Meat Press, 23" X 6", Removable Handle - 233-57A

SKU: 466/233-57Ashowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroomshowroom.title showroom1-3 Week Lead TimeRegular price $462.30 CADSale price $462.30 CAD Regular priceUnit price / per$0.00 CAD

Meat slicers, grinders & patty presses for butcher shops, delis & kitchens

Build a reliable meat station with commercial meat processing equipment sized for real operations in Canada. This collection includes meat slicers, meat grinders, meat grinder parts and accessories, and patty presses from brands like Globe, Vollrath, Prince Castle, Chef'sChoice, Eurodib and Rabco, so you can support everything from deli-style slicing to in-house burger programs.

Whether you’re portioning roasts and cold cuts for a deli, slicing charcuterie in a restaurant or grinding fresh meat for burgers and house-made sausages, dedicated meat processing equipment helps you control yield, consistency and food safety far better than improvised tools or consumer gear.

Types of meat processing equipment in this collection

Use the filters on this page to focus on the equipment that best fits your menu, volume and space:

- Meat slicers: Light, medium and heavier-duty slicers from brands like Globe and Chef'sChoice for deli meats, roasts and some cheeses.

- Meat grinders: Countertop grinders from vendors such as Eurodib, Globe and Vollrath to support fresh-ground beef, pork and other proteins.

- Meat grinder parts & accessories: Plates, knives and other components to maintain cut quality and keep your grinder performing properly.

- Patty presses: Patty-forming presses from brands like Prince Castle and Rabco that help portion consistent burgers and sliders quickly.

Many Canadian operations use a combination of equipment—such as a dedicated slicer for deli meats and charcuterie, plus a grinder and patty press to support a signature burger program. Choosing the right mix helps protect yield, manage labour and keep your meat program consistent across locations and shifts.

Choosing slicers, grinders & patty presses for your menu

Start with how much product you process on your busiest days and what you’re cutting. High-volume delis and grocery-style meat counters typically need heavier-duty slicers with larger blades and more powerful motors, while lighter-duty slicers may be enough for occasional slicing in smaller restaurants, cafés or hotel kitchens.

For grinders, consider the types of meat you run, desired grind size and how often you’ll be grinding. A more powerful grinder with appropriate plates helps you move through batches faster, reduce smear and maintain a better texture. Patty presses then turn that ground product into consistent patties that cook evenly, simplify portion control and support accurate costing.

If you’re not sure which meat processing equipment is right for your Canadian butcher shop, deli or restaurant, start with your peak production windows, the cuts and grinds you need, and available space. If you don’t see a specific slicer, grinder plate, knife or patty press listed here, a Russell Hendrix representative can help you review additional options or alternatives from our vendor partners.

Frequently Asked Questions about Meat Processing Equipment

How do I choose the right meat slicer for my operation?

Start by looking at what you slice most often and how many hours per day the slicer will run. Busy delis and grocery meat departments generally need medium or heavy-duty slicers with larger blades and more robust components. Smaller restaurants that slice meats occasionally can often use a lighter-duty model. Consider blade size, duty rating, ease of cleaning and safety features, and choose a slicer that can comfortably handle your heaviest product without struggling.

What size or power meat grinder do I need?

Grinder choice depends on how many kilograms or pounds of meat you need to grind during your busiest periods and how fine or coarse you want the grind. Higher-volume burger or sausage programs usually benefit from a more powerful grinder that can process batches quickly without overheating the meat. For smaller restaurants grinding occasionally, a compact commercial grinder may be enough. Always match grinder capacity and plate selection to your target grind and throughput.

Can one meat slicer handle both deli meats and cheese?

Many commercial slicers can handle both meats and some cheeses, but performance depends on duty rating, blade design and product temperature. Cheese, especially softer varieties, can be more demanding on a slicer than deli meats. If you plan to slice a significant volume of cheese, look for a slicer rated for that use, keep products properly chilled and follow the manufacturer’s guidelines. In higher-volume operations, some kitchens dedicate one slicer to meats and another to cheese to simplify cleaning and avoid cross-contamination.

How can patty presses help with portion control and labour?

Patty presses form consistent patties quickly, which helps control portion size, reduces hand shaping and makes it easier to train staff. Standardized burgers cook more evenly, simplify costing and reduce waste. For Canadian restaurants and quick-service concepts with busy burger lines, a patty press can significantly speed up prep compared with forming patties by hand, especially when paired with an in-house grinding program.

What are best practices for cleaning and maintaining meat processing equipment?

Meat slicers, grinders and patty presses should be disassembled and cleaned regularly according to the manufacturer’s instructions and your local food safety requirements. That typically includes breaking down blades, plates and food-contact parts, washing and sanitizing them, and allowing them to air dry before reassembly. Avoid harsh abrasives on polished surfaces, and follow any lubrication guidelines for moving parts. Regular inspection and maintenance help prevent breakdowns and support food safety in Canadian kitchens and butcher shops.

What if I don’t see the meat processing machine or attachment I need?

The Meat Processing Equipment collection highlights core slicers, grinders, parts and patty presses from brands like Globe, Vollrath, Prince Castle, Chef'sChoice, Eurodib and Rabco. If you don’t see the exact model, plate, knife or press you’re looking for, a Russell Hendrix representative can help you check additional options, lead times and compatible accessories for your meat program in Canada.